The Belleville washer is a conical-shaped metal disk designed to support high loads with small deflections compared to conventional helical springs. Disc springs to DIN 2093 Group 1 Group 2 Group 3 Disc springs to Factory Standards or other as required.

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

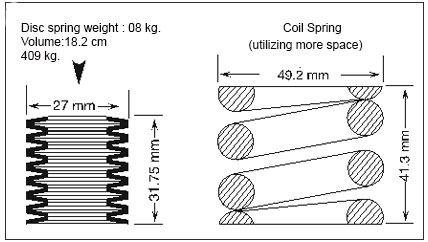

This spring rate is usually very high allowing the spring to produce very large loads in a very small space.

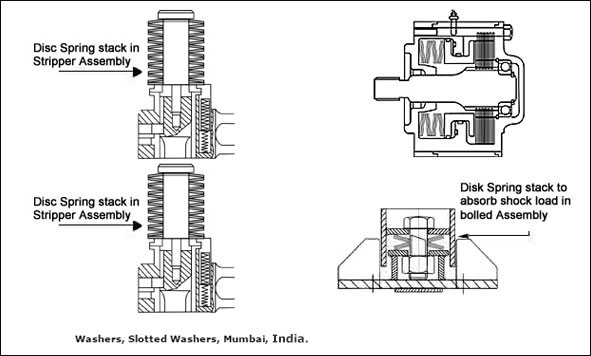

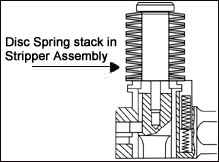

. Disc Springs can be used as a single piece or combined together into different configurations in stacks to achieve the desired force-deflection performance. This washer is often used to reduce vibration thermal expansion relaxation and bolt problems. Outside diameter 60 mm to 800 mm Materials to DIN 2093 DIN 17 221 DIN 17 222 and special.

Product Catalogs Design Guides. The characteristics will be changed and even fatigue cracks can occur. Disk spring design - Roy Mech.

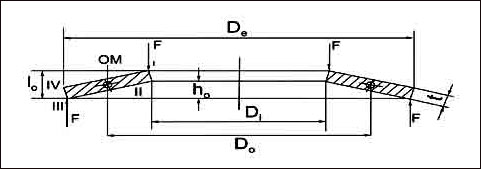

1 sho Fc F De Di lo t ho DISC SPRINGS 2. Our group 1 2 Disc Springs are AUSTEMPERED this method of heat treatment is particularly effective for high fatigue Disc Springs. - Minimizes excessive loads on sensitive equipment.

David Banks-Fear is a Mechanical Design Forum Group member. This is a minimum measurement and reflects the bolt size that the washer will accommodate. What makes Disc Springs unique is.

Ad Design Test Adapt Springs Using Real World Constraints. He is a technical author and consultant design engineer with nearly 40 years of experience. 888-426-6655 ID Represents the washer inside diameter.

Disc Spring Design Guide. Application is a new design or a maintenance requirement Daemars global partnerships offer you one of the most complete sources of supply for Disc Springs. This again causes uneven movement during the deflection of the spring.

At ratios over 2 the Disc Springs may invert when taken towards the flat position. Disc springs always need a guide element to prevent lateral movement. Outside diameter 60 mm to 800 mm.

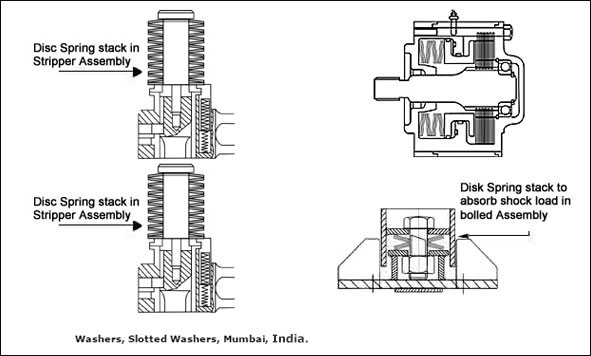

Get What You Need When You Need It. Belleville springs can be stacked in a variety of ways. Spring force The calculation of the force of a disc spring is based on a model by Almen and László.

The guide can be on the outside D e or the inside D i of the springs but inside guidance on a bolt or shaft is preferred to the outside guidance in a sleeve because if offers design and economic advantages. He and his design team are available to assist with any technical design issues with springs pressings and precision engineered parts. Belleville Spring An Overview Sciencedirect Topics Outside diameter 60 mm to 800.

Stock disc springs are available in the following size ranges. Talk With Our Experts Today And Let Us Help You Figure Out The Best Solution. A Belleville spring is a conical shaped disc that will deflect flatten at a given rate.

Disc springs with a thickness of 05 mm and greater are shot-peened to improve fatigue life. What makes the Belleville washer stand out from other kinds of washers is that it can meet all. Standard corrosion protection is phosphating and oiling.

The surface of guide elements is dynamic disc spring applications always has to be harder than the disc springs themselves. Please be cautious and check with your supplier if this product is for virus protection purposes and if the coronavirus COVID-19 will affect your order. The Lee Spring stock disc washer series are available in both imperial and metric sizes and fits common bolt sizes.

Disc springs always need a guide element to prevent lateral movement. 20 Pieces disc spring design guide. Ad Manufacturer of High Quality Disc Springs with Quick Delivery.

A disc spring is a conical shell spring which is loaded along its axis. Ad Next Day Delivery on Motion Control Fluid Power. We have custom design program to assist our customers for their specific applications.

The guide can be on the outside D e or the inside D i of the springs but inside guidance on a bolt or shaft is preferred to the outside guidance in a sleeve because it offers design and economic advantages. Disc Springs are manufactured to DIN 2093 and designed as per DIN 2092. What makes Disc Springs unique is that based on the standardized calcu.

Disc springs are conical washers with elastic properties. Above 15 the Disc Spring exhibits increasingly regressive characteristics and is capable of push-through and therefore needs to be fully supported. Discover the Right Power Tools for the Task at Hand.

These washers have also been used in the. Parallel all springs stacked the same way. Search for a stock disc spring available for same day shipment.

Disc springs to Factory Standards or other as required. 888-SPRINGS 888-777-4647 Fax. Disc springs can used as single or multiple units.

These washers have also been used in the construction of buildings wherein stacks of disc springs are used under buildings as vibration dampers for earthquakes. These in the design stage to get an optimum disc spring solution. Materials to DIN 2093 DIN 17 221 DIN 17 222 and special materials.

14 13 12 11 1 09 08 07 06 05 04 0. Disc Springs are conically-shaped washer-type components designed to be axially loaded. A minimum of 55 HRC is advisable otherwise the surfaces can be damaged.

Disc springs to Factory Standards or other as required Size range. The guide elements and abutments should be hardened if possible to a minimum of 60 HRC. T Represents the washer material thickness as well as the washer solid flat height.

2 Disc Springs are conically-shaped washer-type components designed to be axially loaded. Goodman Diagrams Reporting Tools. Since for most of the designers the disc spring is not daily bread and to many the rules for disc spring design are little known the most important aspects are summarized here.

When stacked in multiple units they can be stacked in series to give a low stiffness value or in parallel to give a higher stiffness value. F c is the design force of the Disc Spring in the flattened position. For the clearance between the guide and the spring DIN 2093 recommends the.

Spring Loaded Design The basic spring loaded pressure relief valve has been developed to meet the need for a simple reliable system. The surface of guide elements is dynamic disc spring applications always has to be harder than the disc springs themselves. By varying the size and the stacking.

Ad Precision Disc Spring Engineering and Manufacturing.

Belleville Spring An Overview Sciencedirect Topics

Belleville Spring Technical Notes Disc Spring Tech Notes

Types Of Springs And Their Applications Smlease Design

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

Disc Spring Din 2093 Disc Springs Manufacturers Suppliers Mumbai

0 comments

Post a Comment